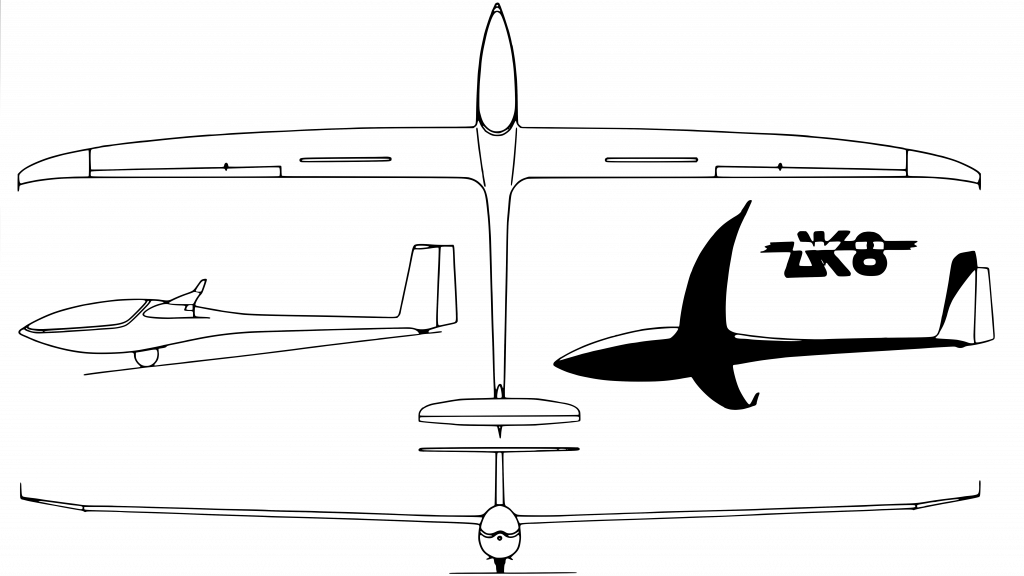

AK-8

The AK-8 is designed as a high-performance glider in the standard class.

Development: 1990 – 1999

Start of construction: Spring 1996

First flight: 17.08.2003

Second maiden flight: 17.10.2009

When building the AK-8, the time-consuming creation of a master positive of the wing was to be dispensed with for the first time and the negative molds were to be milled on the basis of CAD data. This construction method enabled a completely elliptical wing planform without the previously necessary discretization by trapezoidal wing segments.

Initial ideas envisaged a fully elliptical layout, with trailing edge rotary brake flaps also being discussed. In the realized design, the wing depth was slightly increased in the last meter of the half-span in favour of better stall characteristics and winglets were provided. Finally, double-deck Schempp-Hirth flaps were built as airbrakes.

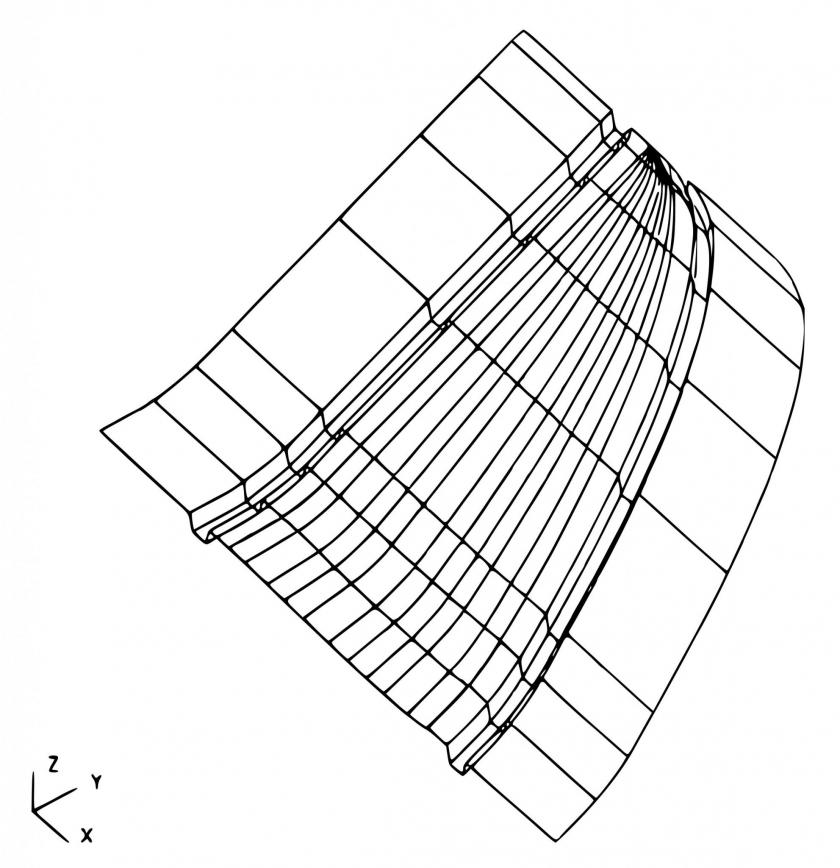

As early as 1991, the first mold segments were milled on a trial basis at the wbk Institute at the University of Karlsruhe in order to test the workflow of CAD design, derivation of the milling paths, preparation of the mold blank and milling frame, milling and assembly of the mold segment on the substructure. The aim was to achieve a high level of geometric accuracy for the finished mold, which should not exceed a deviation of 0.05 mm. The maturity of the available CAD tools made it necessary to program many routines ourselves, such as the generation of the most precise and smooth curves possible from the point clouds used to describe the profiles. In the end, the routine for creating the CNC milling program was developed entirely in-house in order to meet all requirements.

After several trials with different molding materials, aluminum was chosen as the most sensible option. First, blanks were milled from polystyrene, which were embedded in foundry sand and cast.After heat treatment to relieve stresses, these blanks, which were provided with oversize and stiffening ribs, were given their final dimensions by roughing and finishing. The relatively soft surface of the aluminum was then hardened electrochemically to make it resistant to scratches when working with the mold.The individual mold shells were bolted together from several 1.37 m long segments and mounted on an adjustable base to ensure distortion-free alignment.

Initially, Prof. Eppler’s E443, specially developed for the AK-8, was to be used as the wing profile, with the E446 on the outer wing. After the wind tunnel tests, however, it was decided to try an own design, which resulted in several iterations in which the Stuttgart laminar wind tunnel was used extensively, in the DK95-103 by Dieter Kleinschmidt.

The fuselage was initially to be built in the same molds with a modified wing-fuselage transition after the positive experience with the construction of the AK-5 and AK-5b.However, following the insolvency of the Glaser-Dirks company in neighboring Bruchsal, the opportunity arose to insert a modified DG-600M fuselage in a very short time and with the support of the employees. The engine box was omitted and the rear aileron tube was installed later in order to accommodate the changed angle of attack and wing depth. The aileron mixer and airbrake linkage in the fuselage were taken over from the AK-5b in a heavily modified form.

The horizontal stabilizer was to be as small as possible in order to generate as little drag as possible for the high-performance aircraft. In the end, however, a rather large tail surface was chosen compared to today’s 15m aircraft in order to achieve sufficient safety in the difficult to model winch launch load cases. A triple trapeze planform was chosen to minimize the induced drag.

The tailplane shape was produced in the classic design with a positive original, which is why the ground plan can only approximate the elliptical shape.The airfoil used was the then current DU86-137/25 used on the ASW24.

After the last chip of the wing mold milling broke in April 1999, the molds were joined and precisely aligned in the workshop with considerable effort. The outer wings had already been produced in milled Ureol molds. The spar chords were inserted in their own molds and after a large number of small parts (root and end ribs, controls, QR hinges, etc.), spar box and spar web had been completed, the first wing could be glued and demolded in 2001.

The right wing followed in 2002 and the first shell assembly of the entire aircraft. The almost finished AK-8 was presented to the public for the first time at the Aero 2003. The first flight took place on August 17, 2003 in Karlsruhe-Forchheim. Flight testing began the very next day at the Idaflieg summer meeting in Aalen-Elchingen.

On May 6, 2005, the AK-8 suffered major damage during an off-field landing on the Obertsrot sports field in the Murg Valley. The left (inner) wing, the rudder and the right aileron had to be rebuilt. In addition, the spar windings and box as well as the root rib on the right wing were also damaged and had to be replaced.

Before the second maiden flight on October 17, 2009, many small and large jobs had to be completed. After painting and finishing and the successful final inspection by inspector Alwin Güntert, the provisional traffic approval was finally issued and flight testing could be resumed.