AK-11

The AK-11 is the latest project from Akaflieg Karlsruhe, developed as the successor to the AK-X. The development of a new type of wing with a gapless leading edge flap is intended to increase the pre-flight speed and thus achieve a performance advantage over aircraft with conventional flaps. The development is being funded by the Baden-Württemberg Ministry of Science and Art by an amount of 300,000€.

General idea

In order to achieve a significant performance increase over modern competition gliders, a significant reduction in drag is necessary, which is only possible by moving away from conventional aircraft designs with simple flaps. With the AK-X flying wing glider, Akaflieg Karlsruhe has already developed and implemented a very radical design. In addition to the savings in tail resistance with the flying wing, there is also considerable potential in the development of the wing profile. A wing profile that has an adjustable flap on the leading edge in addition to the conventional flap on the trailing edge can generate greater lift in relation to the wing area. The reason for this lies in the changed profile shape: adjusting both flaps increases the curvature of the profile in slow flight position – i.e., especially during takeoff and landing.

To achieve the minimum speed specified by building regulations, a smaller wing area is required for the same lift requirement, allowing the wing to be designed to be significantly slimmer and with less drag. The adjustability of the leading edge flap allows the efficient operating range of the profile to be extended to higher speeds without compromising performance in slow climb.

The Project

The AK-11 project involves the development of a wing with an adjustable leading edge flap and classic flaps, as well as the integration of the wing into an FAI 20m two-seater glider. The leading edge flap is based on a patent by Johannes Achtleitner, an alumnus of Akaflieg Munich. Achleitner Aerospace is supporting Akaflieg in the development of the leading edge flap with its experience in this novel concept – for which Akaflieg is very grateful.

The development of the AK-11 is being funded with 300,000€ by the Baden-Württemberg Ministry of Science, Research, and the Arts as part of the state’s “Future Offensive IV” aerospace strategy. This program supports student groups who contribute to the further development of aerospace with innovative projects and inspire young talent to pursue this field.

Thanks to this funding, Akaflieg Karlsruhe can continue its research work and inspire young people to take an interest in aerospace engineering and the engineering profession.

Challenges

Modern gliders have wing profiles that allow the airflow to remain laminar for a long time. Only at the rear of the profile does the flow become turbulent. Since laminar flows generate less drag than turbulent flows, it is advantageous to keep the flow laminar for as long as possible in order to achieve a higher glide performance.

A laminar-turbulent transition can be promoted, for example, by discontinuities in the profile or flap gaps, as these introduce disturbances into the flow and destabilize it. A flap gap between the leading edge flap and the main wing would cause such a transition and thus lead to significantly increased drag.

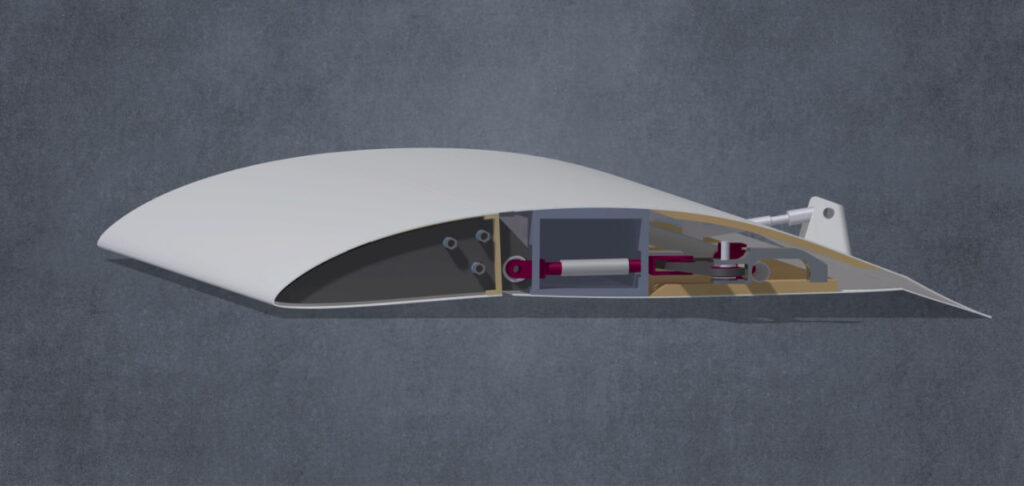

To avoid this, the AK-11 has a continuous laminate on the upper side in the area of the flap gap, which curves smoothly into the leading edge flap during slow flight. This unconventional solution requires considerably more design effort.

Due to the small wing area and the division into flaps and main wing, the installation space in the wing is very limited. Although the AK-11 is exposed to greater loads at high speeds due to its higher pre-flight speed, the wing and its structure are significantly slimmer than those of comparable aircraft. In addition, a more complex mechanical control system and suitable flap guidance must be accommodated in the narrower wing, resulting in high demands in terms of lightweight construction and the clever use of available installation space.

Project progress

The best way to follow the progress of the project is through the articles in our blog.